AMHSA Siemens event – an event of more than two halves

AMHSA Members glean experts’ knowledge and experience in sustainability and cyber security.

Siemens recently opened the doors at their Congleton Production Facility, to other AMHSA members, for a look at their approach and problem solving to two of the most critical problems facing business all around the world today – Cyber Security and Sustainability.

The event was heralded as an opportunity to hear and learn from specialists within the Siemens organisation about their continuing efforts to tackle the problems posed, on a daily basis, as a result of malicious technological espionage-like attacks and the effects of the impact of human action on the global environment. The conclusion and highlight of these presentations was a very special and privileged opportunity, similar to the BBC series, for a “tour of the factory”.

But, the event delivered even more. Delegates were further spoiled with a special introduction from Managing Director, Christian Grosch, who was keen to share his enthusiasm about the flexibility of the Congleton site and its employees and their “we can do and want to” approach to production, research and development and their championing attitudes to Lean Manufacturing / Production methodology within the Siemens organisation.

In addition, we also learned about a major community environmental project, besides more, that had had a positive impact on their community and sustainability credentials.

Sustainability

Sarah Black-Smith and Christine Lowe who have been instrumental and responsible for Congleton Production Facilities’ Journey to Production Net Zero programme and continuing management presented key facts and figures that the site faced in order to reduce targets set by various regulatory bodies.

Whilst auditing all of the facilities – energy consumption, production techniques and processes and wider environmental impacts, the team applied the considerations necessary to drive towards the businesses targets of the site becoming a net zero production facility by 2030.

Whilst all of the usual most common solutions; better lighting, improved insulation, installation of more efficient windows and energy reducing heating systems and facilities were employed, the team also examined and employed newer and more

radical techniques to reduce the dependency on traditional less environmentally friendly energy sources.

Enter Hannah Wildman who explained that through a community partnership, Siemens had introduced the first Hydro Electrical Generation System in East Cheshire. Harnessing the power of the River Dane, a 65Kw Archimedes Screw type generator, relying on the power of water at the Havannah Weir, generates 275Kw hours of carbon free clean green electricity, per annum, for the Siemens site, further helping to reduce the dependency on fossil-based energy generation.

Partners of the project, The Dane Valley Community Energy organisation, help maintain the 250-year-old site providing enthusiastic environmentally conscious helpers, and professional and skilled people too. The project is projected to generate a surplus of energy amounting to approximately £5,000 per annum that will be used to fund other community projects and therefore demonstrating Siemens commitment to the Congleton production facility, local people and local community, demonstrating societal responsibilities.

Whilst, the facility had delivered its net zero carbon production targets early the team were keen to express that they were still on their journey and that they were still pursuing further improvements in their processes which, as a beacon production facility within the Siemens group, might be adopted by other parts of the company in other territories, again signifying the leadership mentality of the Congleton facility.

Cyber Security

One of the most common security threats to many businesses around the globe today, is the threat of a cyber-attack. Thankfully, many companies will not experience the problems of their computer technology suffering rogue malicious harmful viruses entering their technology systems, but those that do or have, will have a tale to tell.

Protecting your information technology is paramount to ensuring the successful continuation of your production or supply chain. Many organisations have experienced the damaging effects or spyware, ransomware or other entering their networks resulting in criminals making financial ransom demands of their victims, often crippling and running into millions of pounds.

Paul Hingley, Siemens Cyber Security expert and who works with the GCHQ (Government Communications Headquarters) and their NCSC (National Cyber Security Centre) explained some of the horrors and disasters that had stunned several large businesses, and some smaller ones too, in the last 20 years.

Many topics were covered and Paul wanted to clearly identify the differences between I.T. (Information Technology) and O.T. (Operational Technology). He was keen to impress on delegates the impacts of cyber attacks on O.T. and the importance for companies to ensure that they had appropriate protection to ensure that attacks were mitigated and defended against.

In their efforts to ensure that their products are defended from cyber attacks for their customers’, in the future all Siemens products will carry their EcoTech labels which clearly indicate the environmental product performance label. It is an environmental declaration based on product-specific evaluations of sustainability relevant KPIs. The labels will also declare conformity and carry information relevant to Information Technology and conformity assessment.

The Tour

The day concluded with a guided tour and overview of the Congleton production facility and explanation of how an upcoming production structure reorganisation project would deliver further productivity improvements within particular product ranges.

The team were on hand to explain the different sections of production from where standard catalogue products and the more beposke items were manufactured. This was a far cry from the days of manual based production lines with lots of labour intensive tasks being undertaken. Today the processes are more scientific and employ increased automated processes with robots and concealed production lines very evident.

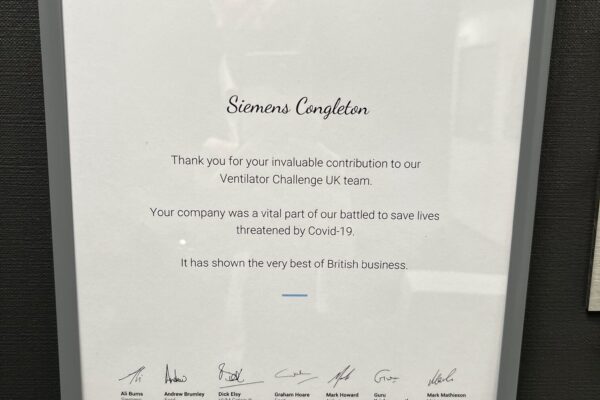

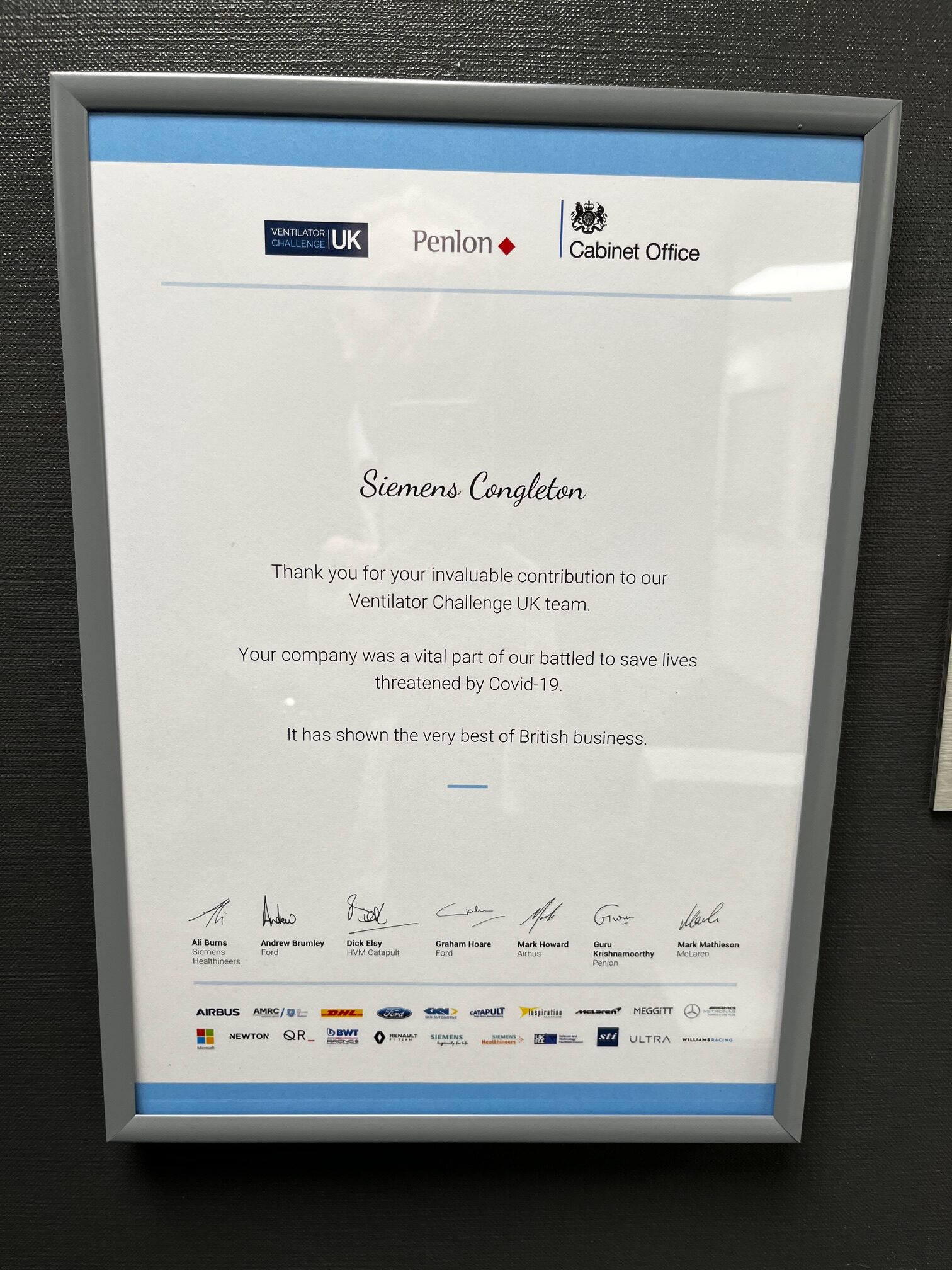

As the tour came to an end we were reminded about the global challenge that the world had faced during the Covid19 Coronavirus Pandemic four years ago, but how the medical scientific and engineering communities had pulled together to find solutions to alleviate the impacts on those most vulnerable within our communities. Siemens engineers had worked tirelessly to adapt their production processes enabling them to manufacture ventilators in desperate need for those suffering in hospitals up and down the land.

Further evidence, should we need it, of the “can do” and “will do” attitude and approach of the whole Siemens workforce at Congleton, who did their part during the Covid19 struggle. Whilst a sobering thought it’s a reminder that humankind will demonstrate harmonious resilience when required.

The group enjoyed an insightful day fostering new and harnessing existing relationships through the networking opportunities. Be sure to join us on our next event which takes a closer look at Automates Storage Retrieval Systems (ASRS) at a live working site. We look forward to seeing you in Mansfield.