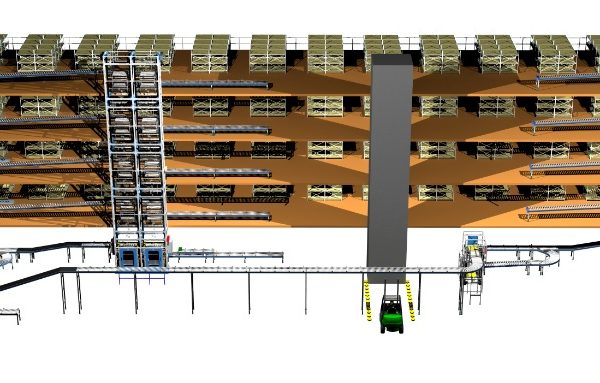

Major projects can be subject to subtle changes when market conditions or environments change. A flexible design approach should be adopted in order to react to the changing demands of your customers, guaranteeing the smooth operation and continuity of the supply chain from inception. Appraisal of the employed system in comparison to the market place is critical to ensure goods are continuously stored, retrieved, archived and most importantly delivered on time in the long term.

Assessing the need of the market and the ability of your supply chain is never easy. However, not impossible. Simulation allows carefully designed modelling, using known conditions and performances, to appraise existing and expected results. A series of timed and recorded simulated activities provides extensive understanding and knowledge of expected outcomes cost effectively before expensive impacts have time to take their toll. Cost effective simulation allows Supply Chain professionals to consider proactive modifications before costly reactive problem solving has damaged reputation.